hardness test vickers method|hv full form in hardness : manufacturer It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter . See more So bucetas de novinhas gostosas em uma super seleção de Fotos só com bucetinhas top. Diversas xoxotas em close pra te deixar com água na boca, tem pepeca lisinha e peludinha pra todos os gostos. Muitos buscam por Fotos de buceta na internet e resolvemos separar nessa postagem somente as melhores. Quem curte imagens de .

{plog:ftitle_list}

WEBRegistro e login nos servidores do Naruto Online. Login do usuário. Lembar conta. Mais métodos. Registrar>> Lista de Servidores. Recomendação. Por favor selecione o servidor conforme a área onde você se localiza para uma melhor experiência. S742:Coelho. .

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size . See more

It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter . See moreWhen doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work . See moreTo convert the Vickers hardness number to SI units the hardness number in kilograms-force per square millimeter (kgf/mm ) has to be multiplied with the standard gravity, $${\displaystyle g_{0}}$$, to get the hardness in MPa (N/mm ) and furthermore divided . See moreIf HV is first expressed in N/mm (MPa), or otherwise by converting from kgf/mm , then the tensile strength (in MPa) of the material can be approximated as σu ≈ HV/c , where c is a constant determined by yield strength, Poisson's ratio, work-hardening . See more

The fin attachment pins and sleeves in the Convair 580 airliner were specified by the aircraft manufacturer to be hardened to a Vickers Hardness specification of 390HV5, the '5' meaning five kiloponds. However, on the aircraft flying Partnair Flight 394 the pins were later . See more• Indentation hardness• Leeb Rebound Hardness Test• Hardness comparison• Knoop hardness test See more

vickers microhardness test procedure

• Meyers and Chawla (1999). "Section 3.8". Mechanical Behavior of Materials. Prentice Hall, Inc.• ASTM E92: Standard method for Vickers hardness of metallic materials (withdrawn and replaced by E384-10e2) See moreThe hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an optical measurement system.

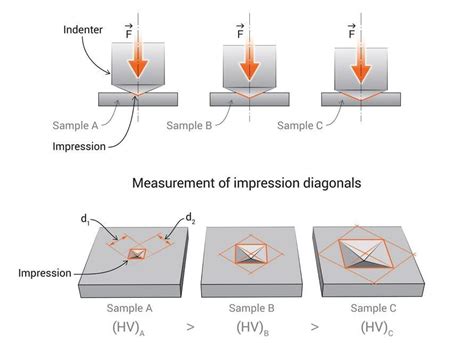

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of . The Vickers hardness test is an industry-standard method for measuring the hardness of metals, plastic, and ceramics. It can be applied to various metals, including high .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the . What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs.

Find an overview of the Vickers methods and their applications depending on the load range as well as an explanation how to choose the right test load.

The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of applications and materials. In conclusion, the Vickers hardness testing method is a powerful technique for assessing the hardness of various materials. Its principles are grounded in precise indentation measurements, allowing for accurate . Hardness testing methods vary based on the material and heat treatment chosen. It’s important that engineers specify hardness testing methods correctly to ensure timely heat treatment and avoid costly delays. .The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. This Vickers hardness test is .

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds use in other materials like ceramics & some polymers, this test is widely employed in the metallurgical area.1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:

Vickers hardness testing, also called microhardness testing, is typically used for small parts, thin sections, or or case depth work. The Vickers method is based on an optical measurement system. The Microhardness testing procedure, ASTM E-384, specifies a series of light loads in which a diamond indenter makes an impression that is measured . Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force . The Rockwell test is described in ASTM E18 – 20 (Standard Test Methods for Rockwell Hardness of Metallic Materials). Vickers Hardness Test. The Vickers hardness test involves the use a 4-sided square-based pyramid indenter, with a precisely defined constant force on the test specimen to evaluate the surface area of the indentation. The . 0.009 807 ≤ F < 1.961 N - Designation: HV 0.001 to

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

ISO 6507-1 Metallic Materials—Vickers hardness Test— Part 1: Test Method 3.2.3 macroindention hardness test, n—a hardness test using ISO/IEC 17011 Conformity Assessment—General Require- test forces normally higher than 9.807 N (1 kgf). Macroinden- ments for Accreditation Bodies Accrediting Conformity tation tests include Vickers .With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te.

For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .The Vickers hardness testing method is often considered a micro-hardness test as it is usually applied to small or thin objects and materials. Following the procedures given in ASTM E384 as the standard for micro-hardness testing, you’ll typically require a diamond indenter with an applicable load range of 10gf and 1kgf to produce an .

What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs. Home; Products. Special Offers. .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can .

Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; Knoop Hardness Testing: Employs a diamond penetrator to impress a sample; . Key hardness testing methods include Rockwell, Brinell, Vickers, Knoop, and Shore. Advanced methods consist of the Leeb rebound hardness test and the Ultrasonic .The Vickers hardness test is specified in this document for lengths of indentation diagonals between 0,020 mm and 1,400 mm. Using this method to determine Vickers hardness from smaller indentations is outside the scope of this document as results would suffer from large uncertainties due to the limitations of optical measurement and . Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. . Improvement of hardness strength relationship and test method (1) Hardness test characteristics. ① The stress state is very soft (α>2), which is widely applicable; The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.

3. Vickers Hardness Testing Vickers hardness testing utilizes a “Vickers hardness testing machine” and a diamond-shaped indenter to measure hardness. This method involves applying a load and measuring the indentation’s diagonal lengths. It is ideal for testing brittle materials, ceramics, and thin sections.The hardness figure is followed by a code indicating the test method. The Brinell and Vickers methods have been used historically in the UK, the Brinell method for softened steels, and Vickers method for either softened or hardened steels. In these tests the ‘diameter’ of the impression is measured. Different materials require different hardness testing methods due to variations in their properties and the type of information required. Vickers Hardness Test. The Vickers Hardness Test is a widely used indentation-based method for measuring hardness. It involves pressing a diamond indenter into the material’s surface at a specified load .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three hardness testing load ranges: in the micro, low-load and conventional (macro) hardness range.

Vickers Hardness Testers. Developed as an alternative to Brinell, the Vickers method was created by Smith and Sandland while working at Vickers Ltd in 1924. Vickers hardness testers are known as microhardness testers. They are types of hardness testers that have a wide-ranging scale, while low forces and a shallow indentation enable the .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is especially valuable for micro hardness testing requiring small, accurate measurements.

vickers hardness test procedure

WEBCaracterísticas: - Todas as 722 cartas possíveis de serem obtidas duelando; - Imagem do results of duel tem o fundo preto, somente com as com as cartas remanescentes do duelo, sobre o campo de batalha. .

hardness test vickers method|hv full form in hardness